The Pepperl+Fuchs TVI58N incremental encoder features a full-size 10 mm shaft and a resolution of 1000 ppr. The rotary encoder has a standard 58 mm diameter housing and is connected via a built-in 0.5 meter cable.

Rotary encoders

Absolute multi-turn rotary encoders provide an absolute step value for each angle setting.

This device has a maximum base resolution of 65536 steps per revolution (16 bits) and encodes up to 16384 revolutions (14 bits).

The PROFIBUS rotary encoder series is based on modern, high-speed single-turn sampling technology and a mechanical multi-turn gearbox. The absolute encoder complies with the PROFIBUS profile.

Pepperl Fuchs RVI58N-1 full-shaft incremental encoders are used to determine the angle of rotation of rotating objects.

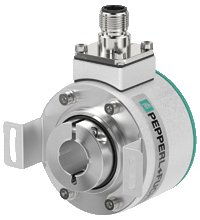

The ENI58IL impresses with its modular design, accessible through all mechanical and electrical interfaces. Combined with its ruggedness, reliability, and versatility, the ENI58IL is the best solution for all common applications. Thanks to its high-precision BlueBeam technology and innovative housing design, the ENI58IL sets a new standard in the incremental encoder market.

Encoder

An encoder is a device that converts angular position or motion into electrical signals. It can be used to control a variety of systems, including robotics, manufacturing, transportation, and medical equipment. Encoders from European and American manufacturers are available for purchase from Power Technology Solutions. We have them in stock and can deliver quickly.

Types of rotary encoders

- Incremental sensors generate signals when their position changes. They generate pulses with each movement, which can be counted to determine angular displacement. Their main advantage is the simplicity and high accuracy of measurements at small angles.

- Multi-turn. Provides a unique value for each position within a full revolution. This allows for precise position determination without the need for resetting or initializing.

Operating principle

- Optical encoders use LEDs and photodetectors to detect the rotation of a disc with printed stripes. As the disc rotates, the light beam is periodically interrupted, creating pulses that are interpreted by the control system.

- Magnetic encoders use magnetic fields and Hall-effect sensors to determine position. They are resistant to contamination and external influences, making them ideal for use in harsh environments.

- Mechanical. These use contact brushes or other mechanical components to generate signals. Although they are less precise and durable than their predecessors, they still find use in some niche applications.

Equipment application

- Industrial automation. In manufacturing processes, encoders are useful for positioning control of machine tools, robotic systems, and conveyor lines. They ensure high productivity, which is essential for automated production.

- Robotics. Here, they are essential for detecting the position and speed of moving parts of robots. This allows for tracking movement and performing complex tasks with high accuracy.

- Medical equipment. In devices such as CT scanners and surgical robots, encoders provide precise positioning and control, which is critical to the safety and effectiveness of medical procedures.

- Automotive industry. In automobiles, encoders are essential in engine management systems, transmissions, and other critical components. They precisely measure and control vehicle operating parameters.

Contact us to purchase an encoder with the optimal technical specifications for your business needs.