One of the main areas of our activity is the design of automated process control systems (APCS) for enterprises.

In our portfolio:

- Development of preliminary design solutions for the automated process control system and its parts

- Development of documentation for the automated process control system and its parts

- Specification of equipment based on technical specifications and design documentation

- Development of design solutions and documentation for electrical engineering

- Selection of equipment based on technical specifications and in accordance with design documentation

Power Technology Solutions specialists design automated process control systems for both newly constructed facilities and existing enterprises.

The development and implementation of an automated process control system (APCS) allows for the optimization and improvement of operational productivity, effectively managing enterprise processes. Properly designed APCS systems reduce the likelihood of human error, thereby positively impacting product quality and process safety.

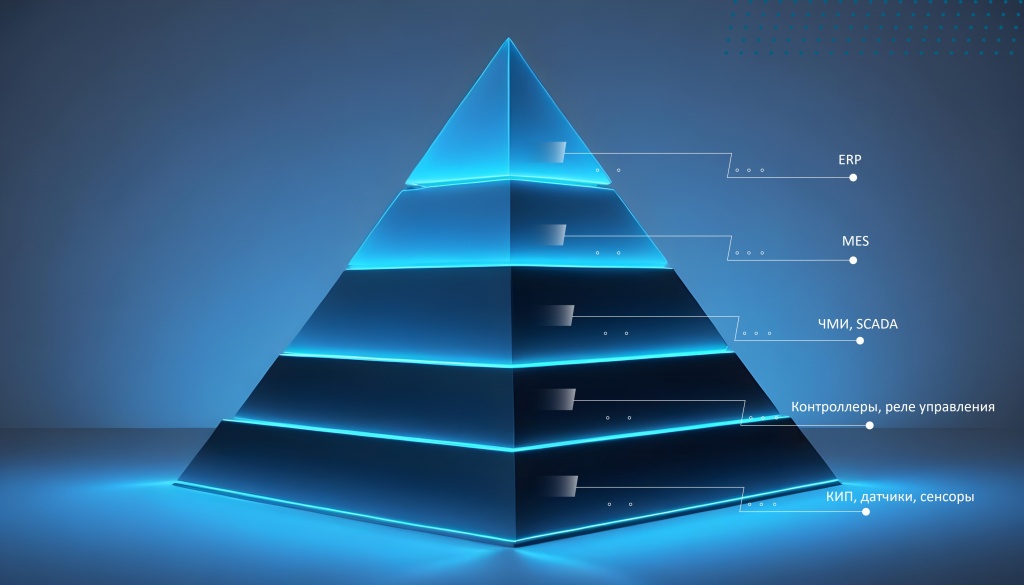

There are 3 main levels of automated process control systems:

-

Lower: Instrumentation, sensors, actuators and mechanisms

-

Average - basic automation level: programmable controllers, relays, counters

-

Upper: human-machine interface level, SCADA systems

Advanced manufacturing companies maximize the potential of their top-level automated process control systems. The top-level automated control system provides extensive capabilities:

-

visualization and interaction of the automated process control system with a person (dispatcher or operator);

-

information and analytical functionality: collection, processing, storage and analysis of information about the parameters of technological processes, and the moments of activation of safety automation, about external intervention of personnel in the operation of the installation, etc.;

-

remote control of equipment and setting of control system parameters.

The modern industrial automation pyramid reflects the development of automation in enterprises, starting with basic control systems and ending with interconnected intelligent production environments, where the upper levels include MES, ERP, the Industrial Internet of Things (IIoT), and advanced cloud technologies.

Our specialists' experience in the design and development of automated process control systems allows us to offer customers both standardized systems and systems created and adapted to the specific needs and objectives of individual enterprises.